Its adaptability to cnc systems is excellent through.

Incremental sheet metal forming a review.

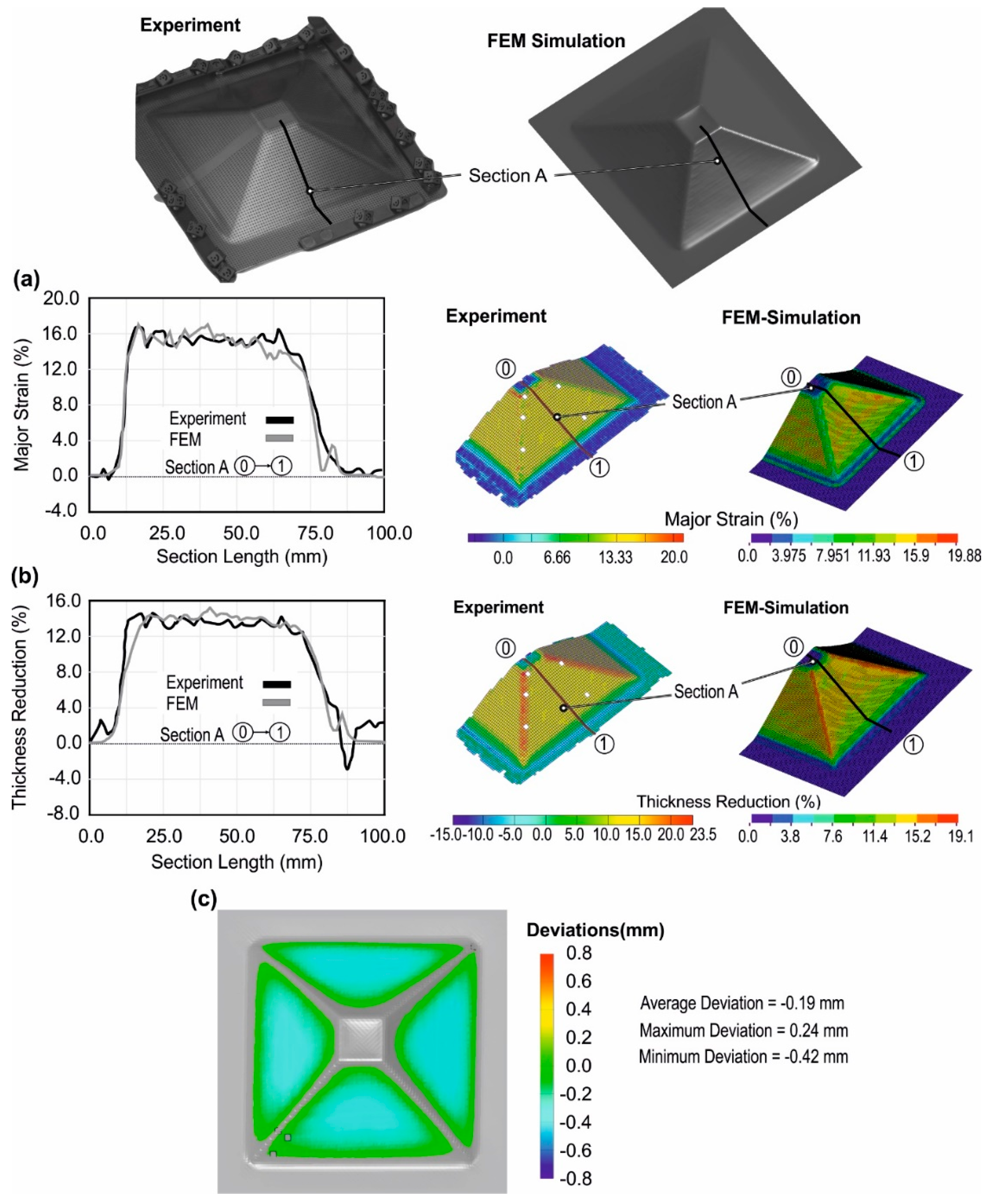

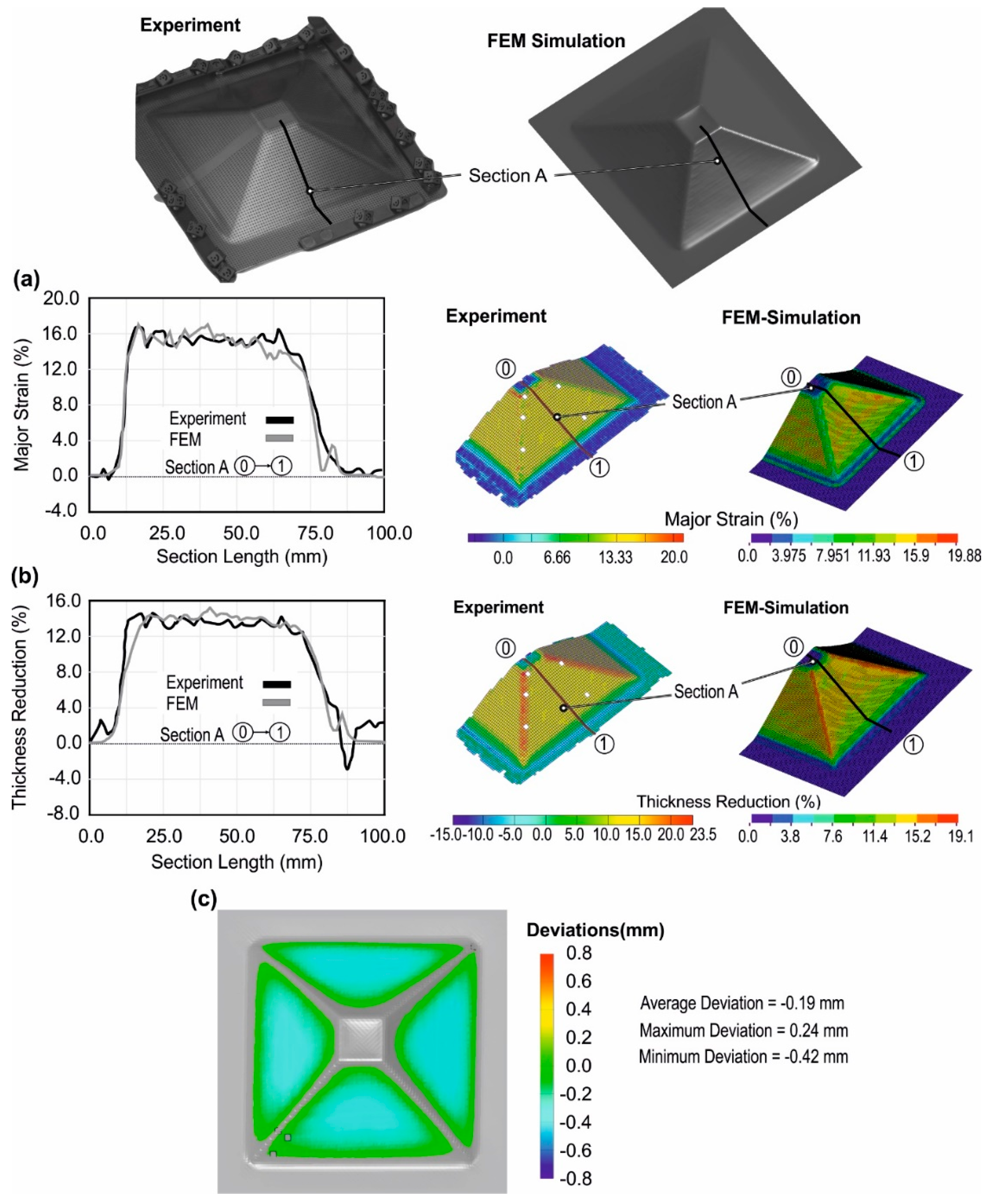

Unlike one step simulation in which only the final part shape is solved incremental forming simulation allows the accurate modeling of sheet forming processes.

In incremental simulations the forming process is divided into steps or increments and the problem is solved incrementally through time.

The drawbacks for the sheet metal forming process are the production rate and part.

In last one decade there has been a continuous increase in study of incremental sheet metal forming isf process among various sheet metal forming processes due to their ability to deform a metal.

The process is agile highly flexible and it able to handle the market requirement.

A particular incremental sheet metal forming process used at large scale is spinning used for the manufacturing of rotational parts in low to medium large series like household cooking equipment.

Incremental sheet metal forming ismf has created significant scientific attention.

Incremental sheet metal forming ismf has created significant scientific attention.

Considering the shortage of current fabrication processes the incremental sheet forming isf which is featured as a flexible forming technique is applied to manufacture implants.

Incremental sheet metal forming is a promising process providing a short and inexpensive way of forming products having a relatively simple but interesting shape.

This paper focuses on what is now generally known as incremental sheet forming isf or asymmetric incremental sheet forming aisf a definition of the process will be given in the next section.

Kuang hua chang in e design 2015.

13 3 3 incremental forming analysis.

The process is agile highly flexible and it able to handle the market requirement.

Incremental sheet metal forming ismf is a highly flexible and versatile process to produce complex sheet metal parts and rapid prototypes.

This paper presents a brief review of the process parameters affecting the.

The drawbacks for the sheet metal forming process are the production rate and part accuracy while high formability and flexibility are consider as main advantage in ismf.